Author: Li Min, SDIC Baiyin Wind Power Co., Ltd.

Abstract: In the drive system of a wind turbine generator set, gearbox is an important part, and the bearing is the key device that directly determines whether the gearbox can operate normally or not. Because the bearing is in a rolling state for a long time, it will have breakdowns that would cause the generator fail to operate normally, and in serious cases the service life of the power grid will be greatly affected. The cause of bearing failure is mainly caused by bearing pitting, high temperature or shaft surface wear. This article focuses on the analysis of the fault diagnosis of the gearbox bearing of the wind turbine generator set, providing a reference for the method used to solve the fault of the gear bearing.

Keywords: wind turbine; gearbox; bearing; vibration; fault diagnosis

The bearings in the gearbox have the functions of transmitting motion, torque and speed changes. Once the bearing fails, it will seriously affect the normal use of the gearbox. 60% of the gear faults are caused by gear failure. At this stage, when diagnosing faults in gearboxes, vibration method, oil analysis method, and chaos system are used. When the gearbox enters the operating state, the components in the gearbox, including shafts, gears, bearings and other parts, will be in a state of vibration. Affected by vibration, the bearings will appear surface pitting; or resulting in the bearing failure due to high temperature, shaft surface wear, etc., which will seriously affect the normal operation of the generator set.

1. Method for gearbox failure analysis

When the gearbox fails, it needs to be fully analyzed by the staff. The main analysis is the error of the gear tooth profile, the resonance of the box body, the bearing pitting, high temperature, the wear of the shaft surface, and the bending of the rotating shaft. Through an in-depth understanding of the fault characteristics of the gearbox, the staff should use acceleration time domain analysis, frequency domain analysis and other methods in accordance with the failure analysis standards to collect the signals emitted by the gearbox under vibration, and the gearbox parameters such as average vibration energy and time domain peak value are used as research objects to judge the overall vibration of the gearbox. By using the speed time domain analysis method, the average vibration energy, time domain signal peak value and other parameters are diagnosed in order to determine the cause of the gearbox failure. The frequency spectrum analysis method is to detect the meshing frequency, acceleration signal and natural frequency of the outer ring of the gear when the gear box is in vibration, so as to find the cause of the gear box failure. At present, the gearbox failure analysis is usually carried out in an industrial field environment. In order to obtain more accurate failure analysis data, the symptom status of the gear is generally detected, and the location and impact range of the gear failure will be truly reflected, to provide the necessary reference for the staff, so as to adopt targeted measures to solve the failure of the gearbox.

2. Diagnosis of typical faults in the drive system of wind turbines

2.1 Diagnosis of the structure of the drive system of the wind turbine

At present, generators and mechanical transmission systems are important parts of the wind turbine system, and they undertake the function of stabilizing the normal operation of the generator set. In wind turbines, gearboxes, generators, and bearings will frequently fail under vibration conditions, especially bearings that are prone to pitting corrosion, shaft surface wear and other failures; and in a high-temperature environment, the gears will be shortened in service life. In addition, as the key equipment for providing kinetic energy for wind turbines, parts such as gearboxes, bearings, and couplings will all be impacted by loads of varying degrees, which can easily lead to failures of the transmission system under different loads.

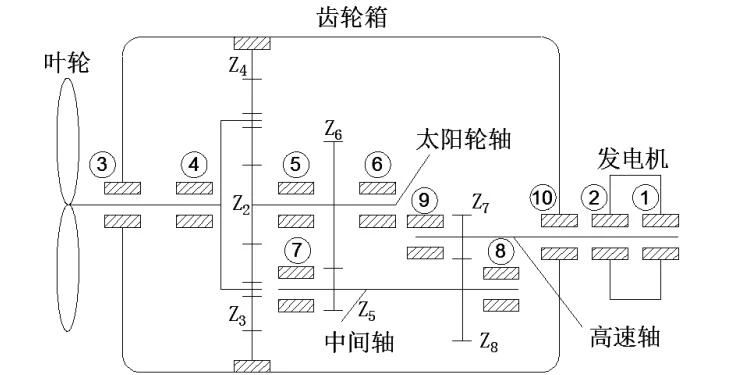

Figure 1 Distribution diagram of measuring points of gearbox and generator

Under the running state of the wind turbine generator, driven by the drive system, the wind energy is converted into mechanical energy, and then the mechanical energy is transported to the generator, and finally electric energy is generated. The transmission system is mainly composed of a main shaft, a coupling, a high-speed shaft and other devices. Each device has a different structure, and the location, range of influence and nature of the bearing failure under operating conditions are also different. The main shaft is a key device connecting the wind wheel and the gear box. When the wind wheel is rotating, the energy is transmitted to the gear box through the change of torque. Under the drive of the gear box, the axial force generated will act on other devices. A coupling is a part that connects two different devices to each other. When the coupling rotates, it will drive the other two devices to rotate together. The power generated in different motion states requires the coupling to have functions such as buffering and damping. The coupling usually consists of a driving shaft and a driven shaft. The high-speed shaft is a device that connects the speed-increasing gearbox and the generator. The high-speed shaft is kept in a high-speed state, which can drive the generator to rotate at a high speed to generate electric energy.

2.2 Typical fault diagnosis of transmission mechanism of wind turbine

Converting wind energy into electrical energy usually requires wind turbines to operate in harsh environments such as strong winds all year round. When designing wind turbines, the minimum temperature is set at minus 20°C. However, the minimum temperature in many areas will be as low as minus 40°C, and wind turbines also need to withstand strong wind, which will increase the load on the unit. It is very easy to cause failure of the transmission system. Especially in the mechanical transmission device, the bearing will have pitting corrosion or shaft surface wear and other faults. If the staff fails to solve the fault in time or fail to replace the faulty parts, the scope of the fault will continue to expand and eventually lead to damage of wind power generating machines.

2.2.1 Gearbox fault diagnosis

Parts such as gears, rolling bearings and shafts are important parts of the gearbox. When analyzing the faults of gears, rolling bearings and shafts, the frequency characteristics and failure characteristics of the vibration signal are usually used to determine the cause of the gearbox failure. During the operation of the wind turbine, it usually maintains a relatively high speed. Once a fault occurs, the parts in the gearbox will be noisy and will be accompanied by irregular vibrations. When detecting the time domain, frequency domain and amplitude generated by the vibration signal, the staff will get a lot of fault data, the most obvious is the gear fault and rolling bearing fault data. Once the wind turbine’s operating speed increases, the above faults will appear .

Wind turbines are usually installed in environments with high winds, generally in harsh areas such as wilderness and islands, and the load generated by the wind has irregular characteristics, and will produce a strong impact on the wind turbine in an instantaneous state, which may cause the wind turbines to malfunction condition. At present, the maximum speed of a wind turbine generator can be as high as 1500 revolutions per minute. During long-term high-speed operation, the gearbox will generate high temperature and heat. At the same time, under the action of the load, it will cause the gearbox to malfunction. At present, common faults of gearboxes include partial faults and distributed faults. Local faults include gear damage, bending fatigue, etc., and distributed faults are divided into tooth surface wear and bearing damage. The forms of failure include the following: First, broken teeth. After the gear is subjected to periodic stress, cracks will appear at the root, and after a long-term load, the gear will break teeth; second, the gear tooth surface fatigue. When the gearbox is in motion, it is affected by mechanical mechanics, and the force generated will cause the gear to slide relatively, but the tooth surface appears pitting, destructive pitting, and surface crushing. The tooth surface of the gear appears in a fatigue state, and the fault state is manifested as the meshing frequency of the vibration signal, the increase of the vibration energy, and the increase of the energy amplitude; third, the tooth surface is glued. After the gear is subjected to high-speed and heavy load, the gearbox is in a high temperature state. At this time, the tooth surface is affected by high temperature and pressure, and the tooth surface will be worn, and when the gear is relatively sliding, the tooth The surface is not sufficiently lubricated, resulting in gluing failure on the tooth surface.

2.2.2 Rotor misalignment fault diagnosis

As a large-scale mechanical equipment, wind turbines are usually placed in the air tens of meters above the ground, and are affected by the wind. It is difficult to install bulky generator sets, and it is impossible to ensure the accurate centering of the rotor. If the rotor cannot be kept in the centering state, at this time, in the long-term operation of the generator set, under the combined influence of wind and high temperature, the damper in the gearbox will deform, causing the rotor and bearings to be unable to maintain the centering state. At this time, the power station unit will vibrate irregularly, causing the axis of the front and rear rotating device to be unable to maintain the same straight line state, which will cause the bearing to fail. In addition to the difficulty of installation, the misalignment of the rotor is caused by the following reasons: First, the rotor in the moving state will change due to the change of this variable, resulting in a difference between the driven rotor and the active rotor. Second, different expansions of the bearing housing of the bearing rotor; third, deformation or displacement of the casing; fourth, uneven settlement of the foundation where the generator is located; fourth, bending of the rotor, triggering the unit Unbalanced rotation occurs.

2.2.3 Fault diagnosis of rolling bearing

In the transmission system, the rolling bearing is an important device. Rolling bearings are generally composed of an inner ring, an outer ring, rolling elements and a cage. The configuration of rolling bearings in the generator set is to take advantage of the high efficiency, easy lubrication and low friction resistance of rolling bearings. However, during the use of rolling bearings, there will be greater noise, and at the same time, they cannot withstand greater impact. If the rolling bearing fails, it is very easy to cause extensive damage to the generator set. In the analysis of rolling bearing faults, the main fault characteristics are divided into the following aspects: First, the bearing inner ring has peeling or pitting. Using the frequency spectrum to detect the inner ring, there will be more obvious harmonic changes; second, the outer ring has peeling or pitting. Use the frequency spectrum to detect, the fault is characterized by no frequency conversion and no amplitude modulation; third, when the rolling element peels off or pits, there will be obvious modulation peak group characteristics at the fault location; fourth, the cage is deformed. Use the frequency spectrum to detect and find that the cage has characteristic frequencies and harmonics. In addition, the failure forms of rolling bearings are divided into the following types, namely fatigue spalling failure, wear failure, crack and fracture failure, and indentation failure.

2.2.4 Fault diagnosis of generator

The generator failure can be divided into stator winding failure and bearing failure. When the stator winding fails, the winding will be damaged, worn, and cracked. At this time, the winding cannot provide insulation. When a bearing failure occurs, different parts of the failure will produce different vibration signals. Taking the rotor misalignment as an example, this type of problem will be classified as an eccentric failure. In addition, the rotor and the stator are supported by bearings, which will bear a large radial load, which will cause the bearing to fail under the action of a large load. Under normal circumstances, the bearing will experience damage to the inner and outer rings, pitting and wear, and the bearing will increase the probability of failure when the bearing is in a state of vibration.

3. Conclusion

In summary, when a wind power generator fails, it is necessary to determine the cause of the wind power system failure from a scientific perspective. Once the wind turbine generator fails, the staff should conduct a full analysis of the traditional system in the generator, and investigate the failure factors of different devices in the system one by one. However, affected by the fault diagnosis conditions, only theoretical basis and test methods can be used to simulate and analyze the faults of the gearbox bearings in the generator set, and the accurate data has not been obtained through the online test method. When analyzing gearbox bearing faults, technologies such as compound fault diagnosis and hybrid intelligent fault diagnosis should be used as methods to detect faults, which will help improve detection efficiency and efficiently handle bearing faults.

Anglų

Anglų Ispanų kalba

Ispanų kalba Prancūzų kalba

Prancūzų kalba Vokiečių kalba

Vokiečių kalba Portugalija

Portugalija Italijoje

Italijoje Korėjiečių

Korėjiečių Japonų kalba

Japonų kalba Vietnamiečių

Vietnamiečių Turkų

Turkų arabiškas

arabiškas Rusų kalba

Rusų kalba Čekų

Čekų Tailandietis

Tailandietis Airis

Airis Bulgarų

Bulgarų Lenkija

Lenkija Kroatas

Kroatas Ukrainietis

Ukrainietis Bosnių

Bosnių Lietuvis

Lietuvis Latvis

Latvis Rumunų

Rumunų Graikų kalba

Graikų kalba Danų kalba

Danų kalba Vengrija

Vengrija Norvegų

Norvegų Suomių

Suomių Olandų

Olandų Švedų

Švedų Slovakas

Slovakas Slovėnų

Slovėnų Indoneziečių kalba

Indoneziečių kalba Bengalų kalba

Bengalų kalba Serbų kalba

Serbų kalba Uzbekas

Uzbekas